Technology

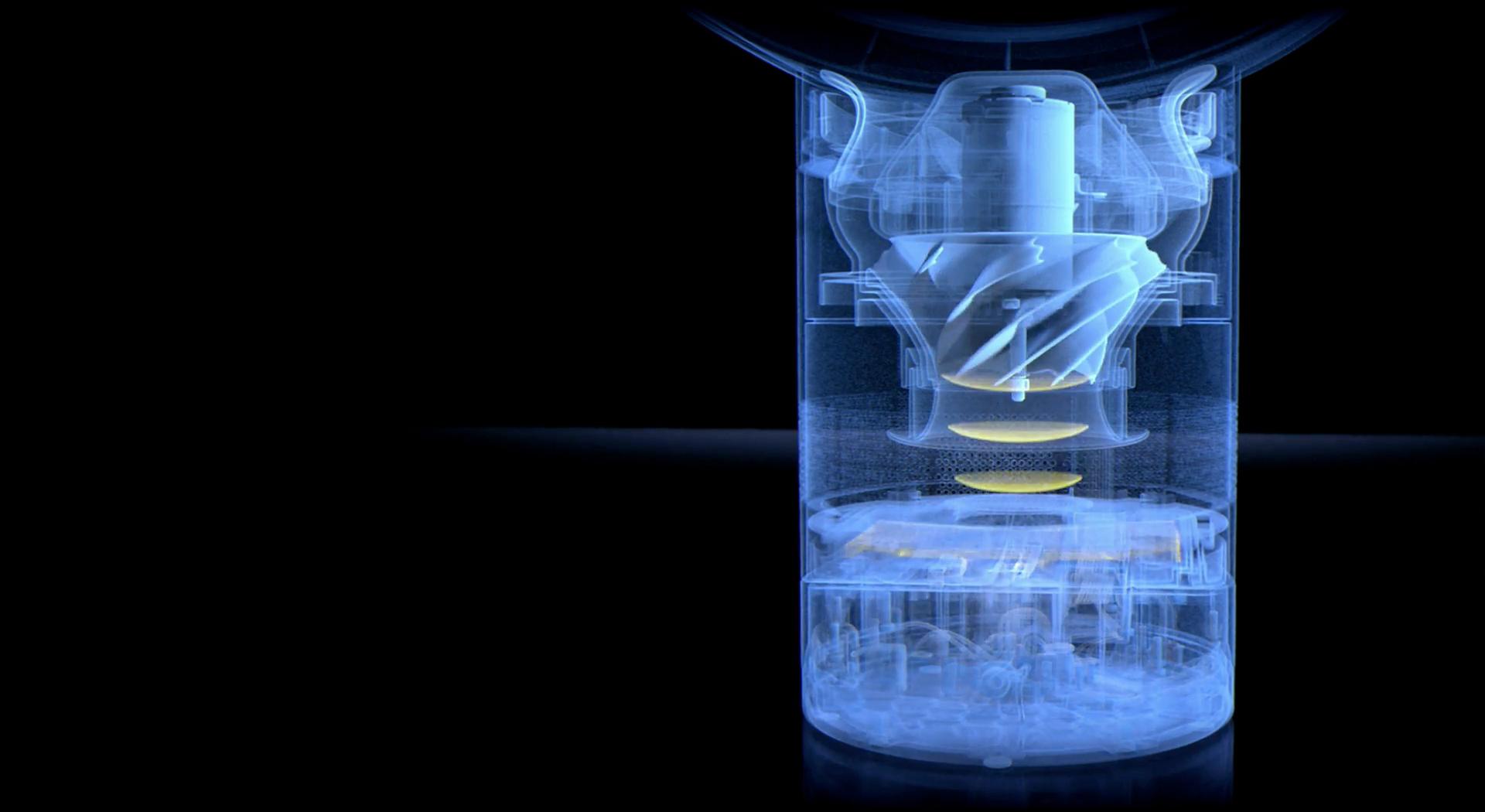

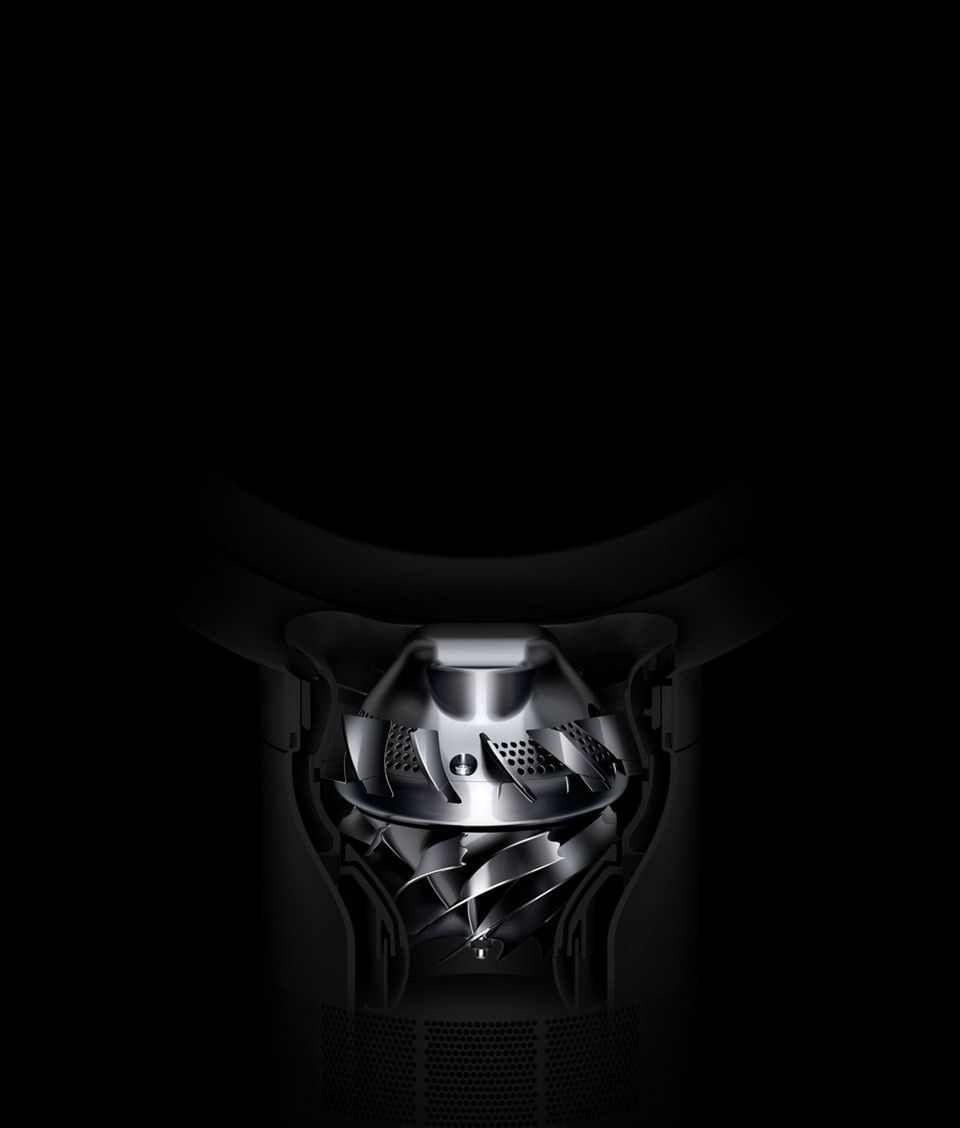

Jet engine technology. Reduced turbulence.

Using technologies found in turbochargers and jet engines, a mixed flow impeller draws air into the machine. The eleven impeller fins are asymmetric, so each one harmonises with the others, balancing the tone. And every one has a scalloped trailing edge, to reduce turbulence and further improve acoustics.

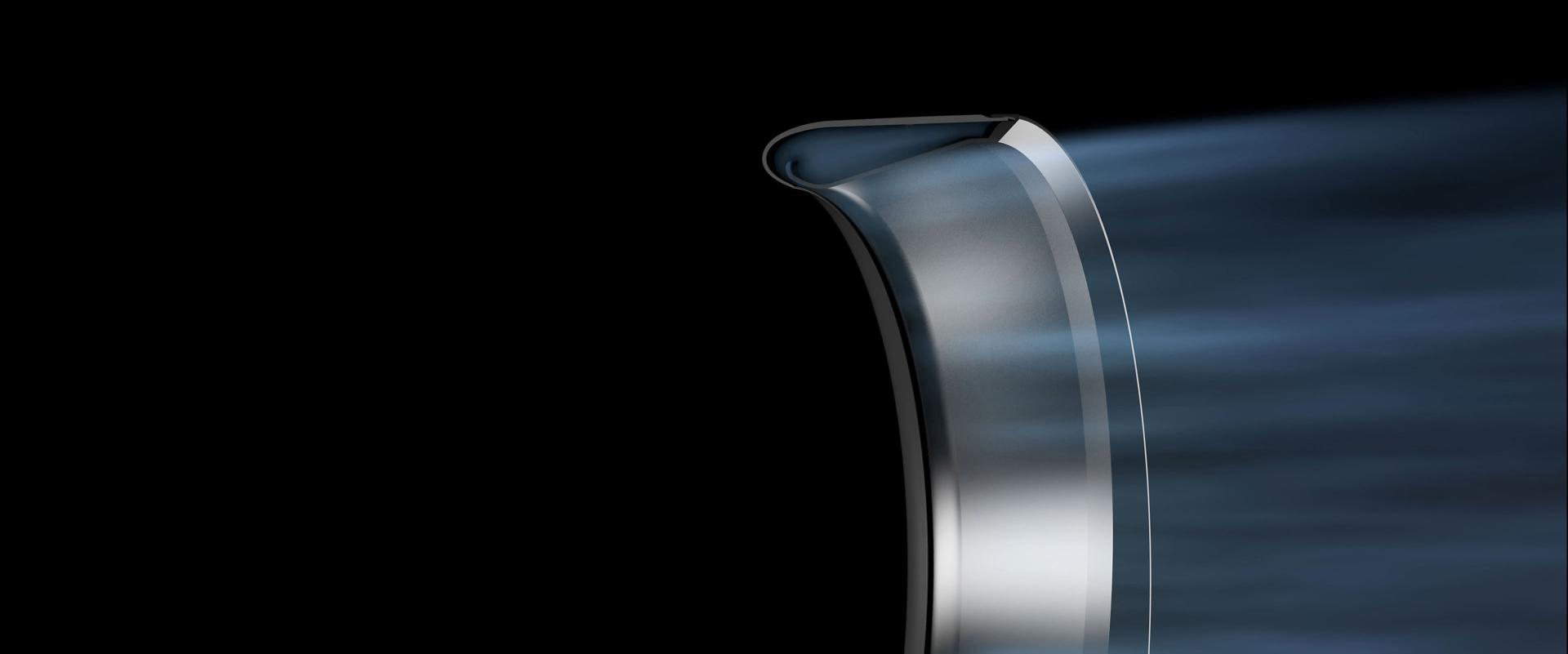

Airfoil-shaped ramp.

After the impeller builds air pressure, up to 38 litres of air per second is forced up into the eccentrically aligned loop. It's then accelerated over an airfoil-shaped ramp, which harnesses the Coanda effect to manipulate the powerful flow of air. Airflow clings to the ramp, which is angled at precisely 16° – channelling its direction for optimum personal fan cooling.

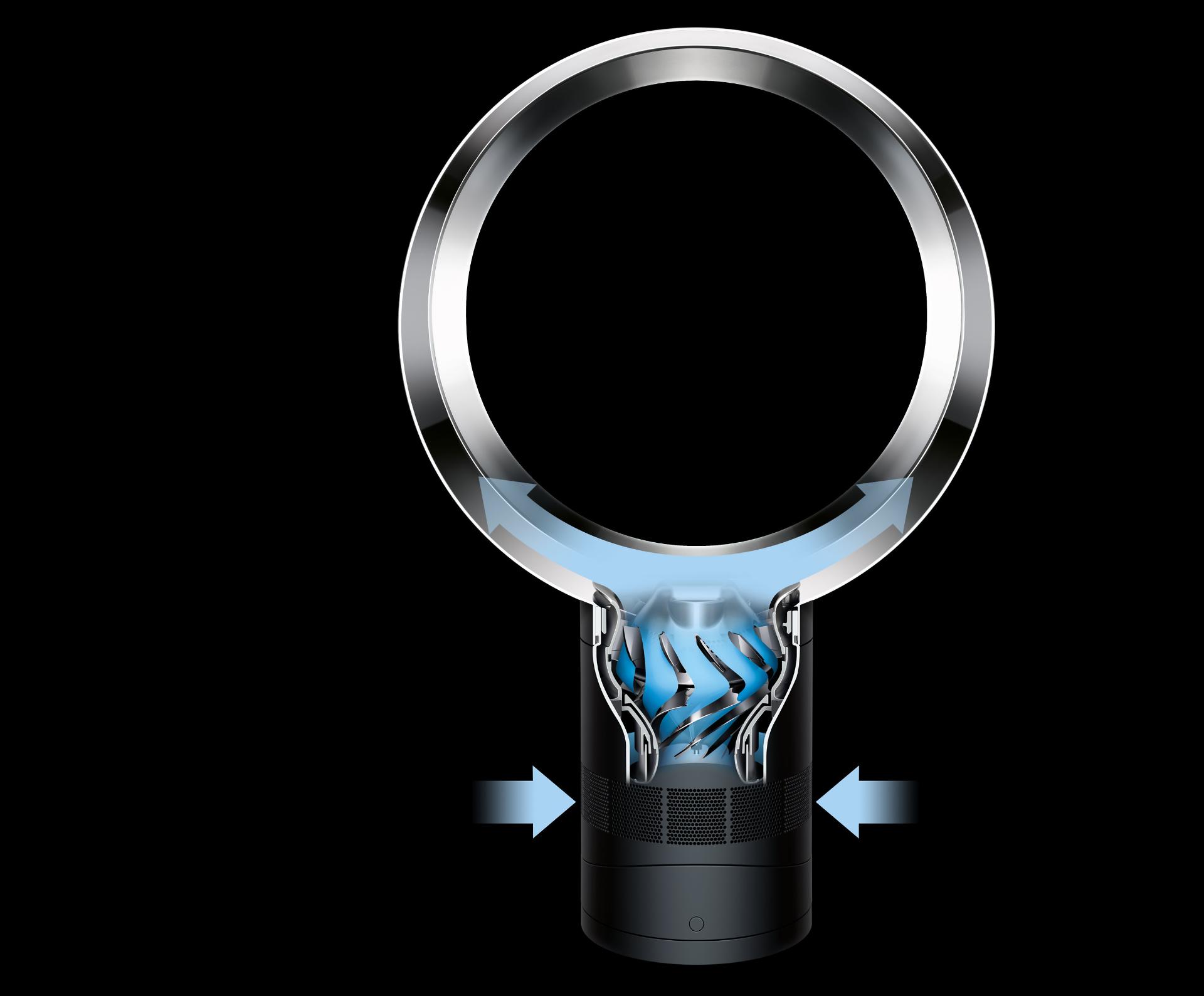

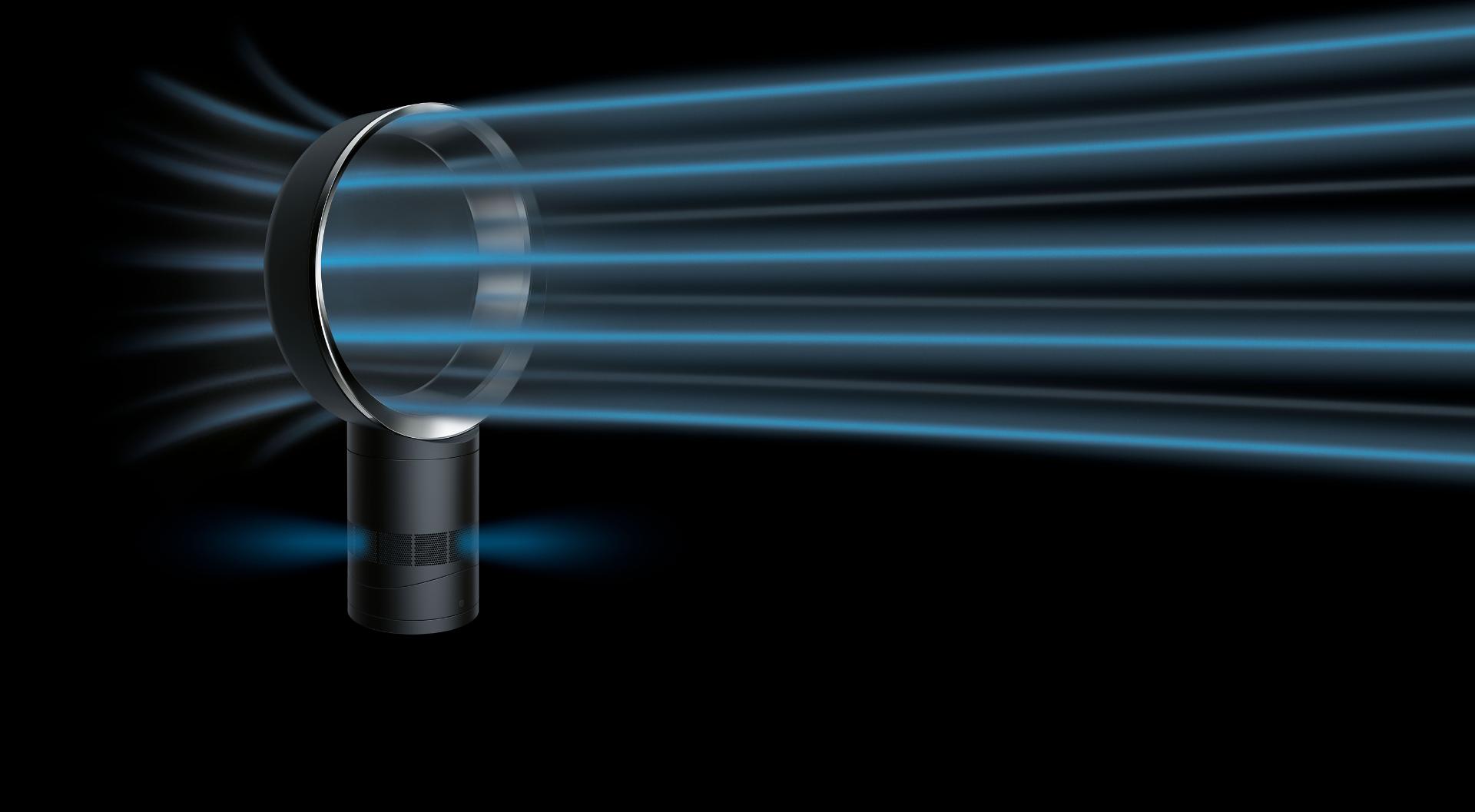

Inducement and entrainment.

Air Multiplier™ technology exploits the Bernoulli principle, which creates an area of low pressure. This induces air behind the fan, whilst surrounding air follows the airflow in a process known as entrainment – multiplying the initial airflow by as much as 15 times.

Helmholtz cavity.

Now housing a Hemholtz cavity, designed to capture and dissipate motor noise. The motor is also calibrated to run slower without affecting cooling performance. And an eccentrically aligned loop allows air to enter with less turbulence, further reducing noise.

Brushless DC motor.

The newly calibrated brushless motor provides variable power, rather than the limited settings on conventional motors. It generates powerful airflow, whilst using less energy.

Aerodynamic diffuser.

Airflow is separated into controlled paths and streamlined, so that air passes through the machine quietly and with greater efficiency. This means the motor can be calibrated to run more slowly while generating powerful airflow, further reducing overall noise.